Information

This panel build is for a customer who required controls for 11 fill lanes that sort large produce into packaging at the end of a conveyor system. The panel needed to have remote access to monitor lanes, maintain speed & reliability all while offering simplicity of control architecture. On the outside of the enclosure we have 2 HMIs that display real time data representative of each lane.

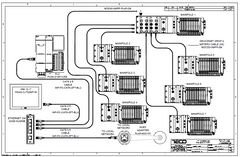

Schematics | Documentation

TECO developed a full schematic that detailed this build from the main power wiring, networking architecture, enclosure design to the panel layout.

All documents on this particular build were shared with the customer. The customer required us to do full integration of their controls for this sorting machine application. Essentially, each manifold corresponds to a function on one lane. This panel build can control 11 lanes. Each lane having 7 functions with the capabilities to run at different pressures.

Products | Features | Benefits

The great features of the program we developed for this customer includes expandability and up front tunability. With a technician screen on the HMIs that include calibration settings which are password protected. By using the IDEC FC6A+ PLC we were able to have the logic, IO, and monitoring requested that will show the custom interface with pertinent information. The Numatics manifolds allow for diagnostics of each coil because of the ethernet cable and wiring within the panel setup.